Workforce Safety

Strengthening our culture and relationships

Every leader, employee and contractor at Devon is expected to actively participate in making Devon a safe place to work. Our values guide us to do what’s right, manage risk, stop work, and support and empower each other to stay safe. We empower our team by providing comprehensive resources to help them work safely and measuring indicators to drive improvement. Setting corporate safety goals and incorporating safety metrics into our compensation focuses everyone at Devon on the actions that will make us safer.

We’re committed to integrating the guiding principles in our Environmental, Health and Safety (EHS) Philosophy into all decisions that affect our operations. Compliance with applicable safety laws, regulations, policies and protocols is one of these principles, and we reinforce it in our Code of Business Conduct and Ethics, EHS Policy and safety orientation, training and engagements.

Our governance structure supports Devon’s commitment to making safety our top priority. The Governance Environmental and Public Policy (GEPP) Committee of our board of directors reviews our safety policies and performance and keeps the full board informed. Devon’s senior vice president (SVP) of exploration and production (E&P) operations is responsible for our safety performance. Our vice president of EHS reports to the SVP E&P Operations on EHS strategy, activities and disclosures.

Devon senior leaders oversee safety policy and performance, with support from the EHS Council. In turn, our workforce is empowered to take the necessary time and actions to perform work safely and stop work if they see a safety risk.

Setting safety and health strategy

To drive continuous improvement, the Devon EHS Council, comprising EHS and operational managers, sets safety and health strategy, helps ensure implementation and tracks the company’s safety performance. The council meets regularly to monitor performance, share lessons learned and engage in roundtable discussions to keep the organization updated on stakeholder expectations for EHS performance.

Contractor management is a key component of the EHS Council’s roadmap and our EHS Management System. Because contractors perform the majority of Devon’s work in the field, contractor safety is a driving factor in our safety performance. We increased our contractor engagements and contractor audits in 2024 to continue improving our partnerships and safety and operational results. The engagements ranged from visits to contractor sites to large events conducted in English and Spanish with contractors that provide like services.

To strengthen our workover rig operations, we formed a project team focused on workover automation, culture, key performance indicators (KPI), organizational structure and partners. As a result, we shared learnings about new technologies scoped or trialed in the field and initiated data acquisition for KPIs. We also cohosted a roundtable with a third-party software developer for over 20 operators to discuss opportunities to advance technology and partnerships for workover rigs. In 2025, we’re using lessons learned to better align execution and engineering teams, deploy software fleetwide for more targeted tracking of crew turnover and experience levels, and publish new KPIs for workover operations. Work is also underway to host the second roundtable with peer companies and contract partners.

EHS Council members and Devon safety leaders proactively engage with peer companies in our operating basins to improve company and industry performance in safety, public policy, the environment and other key areas. Devon is a member of the American Exploration and Production Council (AXPC) Health and Safety Subcommittee. At the AXPC Safety Symposium in 2023, the Devon CEO, vice president of EHS and safety team members represented the company in discussions about industry safety. As a result of the AXPC symposium, Devon continues to participate in the safety share program with other industry operators. Devon continued our longtime sponsorship of the OSHA Oil and Gas Safety and Environmental Conference in 2024. A Devon health and safety leader was a founder of the conference and one of our EHS supervisors is an active member of the event’s advisory board. We’re a member of the Onshore Safety Alliance (OSA), a voluntary industry coalition committed to reducing SIFs in U.S. onshore oil and natural gas operations

In 2025, the safety team will work toward meeting a higher corporate safety performance goal, including executive committee reviews of trends from SIF investigations throughout the year. Additional focus areas will be workover operations, due to our increasing workover rig count; dropped objects on both drilling and workover operations, which account for one-quarter to one-third of SIF events across our industry; contractor management; and peer benchmarking.

We will also focus on continuous improvement in four management system elements: asset integrity, safe work practices, training, and records and documentation.

In addition, we’re implementing a variety of artificial intelligence (AI) tools and drones, and exploring artificial reality and virtual reality for safety training, wearables and other technologies that can help keep people safe in the field.

Building on our positive EHS culture

Encouraging a strong EHS culture at Devon is a priority for the EHS Council and the broader organization. We believe that the care and concern we show our workforce can have a positive impact on their safety and health at work and at home. We’ve learned from our field leaders that transparent communications, positive safety behaviors, proactive reporting and safely meeting operational goals are both signs and outcomes of a healthy EHS culture. The council assesses our EHS culture regularly to identify the most effective approaches and programs to foster strong safety performance.

We begin instilling our safety culture on an employee’s first day on the job. During new-hire orientation, they learn the safety behaviors we expect and incorporate into the employee appraisal process: visible commitment, accountability, anticipation, participation, recognition and communication. We keep the safety conversation and engagement going throughout their career.

Job competency is one of our EHS guiding principles, and we emphasize the quality of safety training over the quantity. A combination of online and hands-on training is offered to office and field workers based on their job responsibilities. All employees and contractors must complete our field safety briefing if they work on or visit field locations. Contractors also must complete our Devon Orientation through our third-party contractor performance network. Our training reinforces our requirement to immediately report any incident or near-miss event and to be accountable for our own and others’ safety.

To foster our positive EHS culture and behaviors, our Safe Work Award Program (SWAP) recognizes and rewards proactive reporting of workplace hazards, instances where work was stopped due to the identification of a safety concern and good environmental catches. Both employees and contractors are eligible, and awards are presented at monthly safety meetings. Additional awards are given on a quarterly basis for the ‘best of the best.’ In addition, our drilling, completions and workover teams recognize good stops by our contractors each month across all our operating areas. In 2024, 270 employees received SWAP monetary awards and 250 contractors were recognized with Devon branded items like coolers.

Engaging our workforce

Our Hearts & Minds workshops have been a core element of our safety engagement efforts with service, rig and contract drilling crews and leaders across Devon since 2014. During the workshops, we share our safety culture and approach to effective communication, continuous improvement, integrity and situational awareness to reduce safety risk.

We adapt the content to meet the needs of our workforce and business. In recent years, this led us to initiate honest discussions about mental health and tools to address mental health issues, including Devon’s Employee Assistance Program and suicide prevention and crisis hotline information. In 2024, we emphasized the importance of our Life Saving Rule to come to work physically and mentally Fit for Duty. Hearts & Minds continues to be a place to talk openly about challenges and listen to our workforce as we drive home why safety is so important to Devon.

We delivered Hearts & Minds to 574 employees and contractors in 2024. To reach and engage even more people, the Delaware Basin team provided Hearts & Minds workshops for specific categories of service providers with the highest risk/highest exposure.

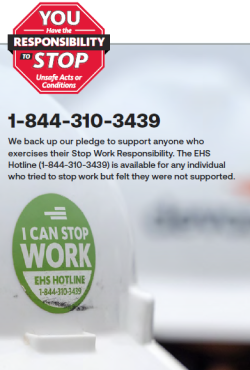

Stop Work Responsibility

Proactively managing safety risks is a key factor in maintaining safe working conditions. Starting with new-hire safety orientation and continuing on our work sites, we emphasize the importance of Stop Work Responsibility. Employees have the right, responsibility and obligation to speak up and stop any action, task or behavior that is or could be unsafe. It’s also a way we live our value of courage, and Devon pledges to support anyone who exercises their Stop Work Responsibility. We capture and track proactive stops and good catches, and recognize individuals for stopping work to safeguard themselves, each other and the environment.

Contractor relationships

The contract vendors who provide work in the field are vital to safe, environmentally responsible and efficient operations, and building relationships with them to succeed as one team is a Devon value. We seek to work with contractors who have the strongest safety programs and track records, and we strive to work only with approved contractors who complete our supplier qualification process and meet our substantial policy and insurance requirements. Contractors are responsible for having EHS programs that meet or exceed all federal, state and local laws, rules and regulations, as well as Devon’s standards and protocols for essential safety activities.

As part of our supplier risk assessment process, we use ISN for third-party contractor verification and management. Our third party software allows us to monitor a contractor’s compliance with our EHS, insurance, OSHA verification and other requirements, and enables contractors to upload needed documentation. In addition, we use a separate third-party service to monitor contractors’ compliance with our drug and alcohol policy.

We require contractors to perform high-quality, safe and environmentally sound work. Contractors are expected to provide and retain quality personnel who are adequately trained to perform their jobs safely. Devon works constantly to raise the level of contractor safety performance through training and engagement.

Contractors must complete the widely used SafeLand, RigPass or equivalent safety training to work with Devon, unless specifically exempted by our EHS Contractor Management practice. These programs and Devon’s contractor safety orientation are available on the Veriforce eLearning platform. This orientation reviews critical safety rules for specific activities performed on field locations, such as fall protection, confined space, hot work, energy isolation, spill prevention and waste management. Oil haulers and all other contractors who work in transportation must complete safety briefings specific to their work. Devon’s company website provides contractors with easy access to our safety requirements, expectations, protocols, Safety Data Sheets (SDS), forms and tools.

We evaluate contractor compliance with the requirements to work on Devon locations. Our operations teams can review the evaluation results daily on our intranet to help them choose appropriate contractors for their needs.

Leadership engagements in the field can have a positive impact on our workforce, safety performance and operational excellence. Our field personnel wear hard hat stickers that say “Ask me my reason for working safely” to encourage safety-related engagements. The conversations that result often reveal that people work safely so they can return home to their family and friends — a higher motivation than simply following procedures.

To continue building relationships with contractors, our field safety professionals work with each of our business units to select contract companies to audit. The goal of audits is to identify opportunities for EHS performance improvement. Safety professionals and field operations leaders review contractor EHS programs, make field visits and interview contractor crews to ensure their understanding and alignment of these programs. If issues are found, they develop action plans to help bring contractors up to standard.

We performed 29 audits and 47 general engagements with contractors in 2024, a significant increase from 2023. The largest event was conducted in English and Spanish for more than 150 contractors in our Powder River asset. Devon recognized crews with awards and discussed SIFs to raise awareness. Contractors have responded favorably and say these events are valuable. Based on the positive results, we set a goal to increase the number of audits and engagements by 25% in 2025. We also plan to continue hosting meetings with contractors who provide like services to discuss safety trends and our expectations.

Auditing field and process compliance

Audits to identify and correct safety concerns are an element of Devon’s EHS Management System. Each business unit is required to perform an annual safety self-audit of compliance with regulations and our EHS protocols. Findings of noncompliance and suggestions for improvement are recorded in our Incident Management System (IMS) and tracked to closure. Business unit EHS professionals lead the audits, with guest auditors from other business units on hand to share best practices and lessons learned.

More than half of the audit time is spent at field locations, focusing on sites where work is under way so auditors can engage employees and contractors. Auditors check training, competency and inspection records and other documentation. We share trends observed and lessons learned during audits across the company to drive improvement.

Devon’s internal audit team provides an additional layer of review by performing operational audits in our field offices to examine processes and controls for supply chain, inventory, fleet management and other functions. Internal audit periodically assesses the field audit process and recommends improvement opportunities.

Committed to improvement

Devon sets annual corporate safety goals to focus our efforts to improve performance. Our emphasis is on preventing serious injuries and fatalities (SIF) so our employees and contractors can return home safely every day.

We surpassed our safety performance goals in 2024, recording a 35% reduction in the SIF actual rate and an approximately 30% reduction in contractor recordables compared to 2023. We believe that emphasizing safety engagements and audits was an important contributor to our improved performance.

Devon ensures all SIF events are investigated either internally or by the contractor involved. For internal investigations, Devon EHS professionals utilize the TapRoot platform to determine root causes and corrective actions. After the investigation is complete, it is presented to business and EHS leadership and shared across the company.

We use SIF learnings throughout Devon to prevent future occurrences. We distribute SIF Safety Bulletins to operations leaders that describe a SIF, the initial investigation findings, actions and next steps. Our operations teams discuss the information with contractors working on our locations. Feedback from our field teams indicates that the bulletins are an effective, simple tool to spark a safety conversation with our employees and contractors before they start work.

We also review SIFs where no one was injured (potential or near miss) and industry SIFs to better understand trends, mitigations and best practices. As a founding participant in the Onshore Safety Alliance (OSA), Devon committed to support the OSA guiding principles, industry sharing and learning, and to carry out a Life Saving Actions program, risk assessments, incident investigations and other safety actions. In addition, we collaborate with a variety of peer groups to study near misses, and identify preventive measures to help improve safety throughout our industry.

To give a comprehensive view of our safety performance, Devon also tracks the Days Away Restricted Rate (DART), Lost Time Incident Rate (LTIR) and Total Recordable Incident Rate (TRIR) for employees and contractors. In 2024, our TRIR (for employees + contractors) dropped 15% compared to 2023 with a rate of .45 while hours worked was only 9% lower than 2023.

Driving is one of the most dangerous activities for Devon employees, who drove over 20 million miles in 2024. Our “Engage Your Mind, Then Drive” safe driving campaign encourages a pre-job planning approach to driving to positively impact Devon employees, their families and communities. Devon requires employees who have assigned vehicles to take hands-on commentary driver training.

2025 corporate safety goals

Devon’s 2025 corporate safety goals continue our mission to protect the lives of our employees, contractors and communities. Based on our underlying metrics, the goals are weighted toward year-over-year improvement in our SIF rate, and demonstrate our level of commitment to safety and to delivering a superior safety culture.

Safety accounts for 15% of the overall corporate scorecard in 2025. SIF actuals represents the largest portion of the safety goal. Utilizing SIF learnings to reduce SIF exposure and events and improve processes, culture and workplace safety remains a companywide goal for the seventh year.

Guided by our values to always do what’s right, support each other and proactively manage risk, we continue to empower the entire Devon team with the culture, tools and processes to work safely.