Well Safety

Ensuring well integrity

Devon uses proven best practices, technologies, tools and materials to protect people and the environment throughout the life cycle of our oil and natural gas wells.

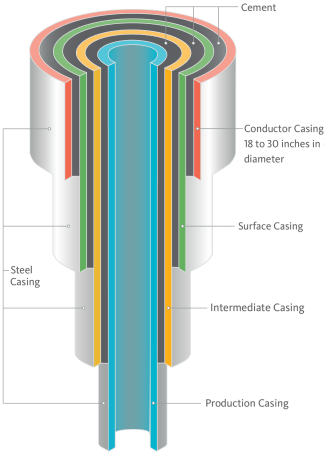

Well integrity starts with the planning and design of the wellbore, including the selection of equipment, materials and drilling techniques. Devon designs our wells to meet high standards for the strength of the steel pipes that form the well, known as casing, and the quality and quantity of cement we use to separate and protect the multiple layers of casing. This attention to well construction keeps fluids in their proper place and protects groundwater zones for the life of the well.

During drilling operations, pressure tests confirm casing integrity. Acoustic measurements let us know that the cement is properly bonded to the casing and to the surrounding rock formation. Employees working in our Well Construction area are focused on optimizing drilling and completion engineering, monitoring Devon wells and making adjustments to prevent issues before they occur.

Devon continues to verify the well’s integrity during production operations by monitoring tubing and casing pressures and by analyzing gas and water produced by the well. We also conduct periodic pressure tests and casing inspections.

We determine the drilling fluids to be used during the design phase before we drill a well. We conduct regular well-control drills on our drilling rigs and audit drills as part of our field review process. To prevent spills, Devon follows local, state and federal guidelines when handling drilling fluid and mud systems.

After a well is drilled, we use the hydraulic fracturing process to complete it. Water, sand and additives are pumped into the wellbore to create or restore small fractures in the rock to stimulate production from new or existing oil and gas wells. Water and sand make up 98% to 99.5% of the mixture. A full registry of wells and chemical additives, along with much more information about hydraulic fracturing, is available at fracfocus.org. Devon played a leading role in creating Frac Focus in 2011 and has remained a major contributor to the site.

We regularly communicate Devon’s environmental, health and safety policies, protocols and operational expectations for well safety in safety tailgate meetings at field locations. We pride ourselves on work safety and empowerment; all our crews have Stop Work Responsibility. Anyone can stop a job at any time if the person notices a potential hazard or is unsure about a task. This workplace culture helps keep people safe and protects the environment by reducing the risk of spills and emissions.

A full registry of wells and chemical additives, along with much more information about hydraulic fracturing, is available at fracfocus.org.