Operations Overview

Operational excellence and EHS

Devon Energy strives for sustainable growth by delivering oil and gas from our portfolio of premier assets in a disciplined, capital-efficient and responsible way. We give equal focus to operational excellence and our environmental, health and safety (EHS) performance to drive business progress and keep our social license to operate for decades to come. We’re guided by our values to always do what’s right, earn trust, take intelligent risks, and make a positive and sustainable impact.

Devon finds and produces oil, natural gas and natural gas liquids in the most prolific basins in the U.S. By helping to supply reliable, affordable energy, we create jobs, strengthen our communities, and contribute to local, state, federal and global economies. We’ve pioneered operational best practices, proactively applied advanced technologies, and adapted to evolving market conditions, regulations and stakeholder expectations. We do this while actively mitigating our environmental impacts, including setting and investing in meeting ambitious targets to reduce our methane emissions and address stakeholder concerns about climate change and other issues.

Our operating teams are accountable for superior operational execution, protecting people and the environment, and complying with all applicable laws, regulations and company policies. Through continuous improvement in operations and EHS performance, we’re able to increase efficiencies, lower costs and reduce our environmental impacts. To reinforce the importance of EHS results, we tie a portion of our annual compensation to achieving corporate EHS targets.

Our cross-functional EHS Council sets our strategy and priorities for improving EHS performance, and regularly communicates plans and progress with our operating teams. EHS professionals in our field operations support our teams with timely guidance and effective policies, protocols and practices. To safeguard our workforce, Devon’s operating teams work proactively to strengthen our safety culture, share lessons learned, identify trends, and track leading and lagging indicators. We strive to work with contract partners in the field who have strong EHS programs and track records.

We evaluate and apply the latest technologies, tools and best practices to improve our environmental performance. One of our top priorities is to accurately measure and mitigate greenhouse gas (GHG) and methane emissions and meet our short- and long-term emission reduction targets. We have significantly reduced flared volumes from our operations and steadily increased the number of voluntary leak detection and repair (LDAR) surveys performed on equipment. Devon has reduced our need for freshwater in our highest-activity basins by increasing our recycling capacity and the volume of recycled water we use. We also seek to limit the use of freshwater as much as possible. Devon is committed to land conservation and seeks to protect biodiversity by minimizing our operational footprint and impacts to land, wildlife and their habitats, and cultural and historical resources.

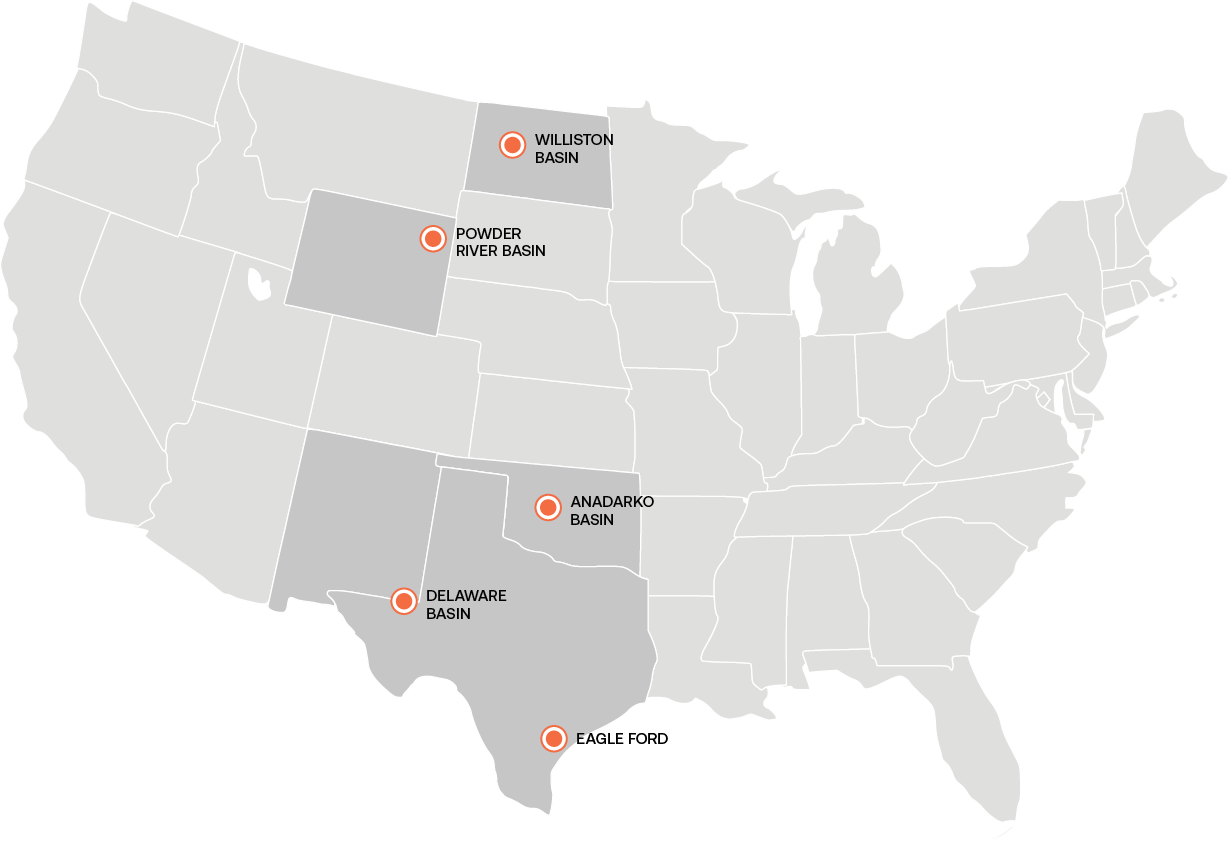

Diversified portfolio across U.S. resource plays

Devon operates premier acreage positions with a deep, high-quality inventory of drilling locations. Our focused development plan centers on drilling activities in our core areas of the Delaware Basin of southeast New Mexico and west Texas, the Eagle Ford Shale in South Texas, the Powder River Basin in Wyoming, the Williston Basin in North Dakota and the Anadarko Basin in western Oklahoma.

We’ve positioned Devon for sustainable growth through a disciplined, returns-driven strategy, significant financial strength and liquidity, and an advantaged dividend. Our commitment to sustainability supports our growth by keeping us focused on managing risk, operating responsibly and improving continuously.

Technology innovation and differentiation

As a long-time industry innovator that holds multiple patents related to drilling and completions operations, we strive to differentiate our company through our technology use. Devon invests in, develops, deploys and investigates advanced technologies to optimize production, enhance business decision-making processes, improve safety and protect the environment.

Devon invests in a dedicated technology team and embeds technology professionals in our business units to align solutions to business needs. For example, we use a carbon accounting platform that was developed collaboratively by software developers, data engineers and data scientists on our technology team and domain experts from our sustainability and EHS teams. The platform enables us to calculate emissions at the facility equipment level instead of at the traditional basin level, which improves emissions data precision and reporting methodologies for regulatory standards and frameworks that are developed. As a result of prioritizing this proactive project, Devon is also better able to set and meet our goals for reducing GHG and methane emissions intensity.

Advanced emissions detection, quantification and mitigation technologies are a key component of our strategy for broader emissions reductions to reduce our environmental impact. We established a testing facility where we evaluate and compare multiple technologies that would allow for faster detection and mitigation of methane emissions in an economically feasible way. We continue to assess technologies to enhance flare performance and identify small fluid spills, while also focusing on water-related technologies aimed at beneficial uses of produced water beyond our industry, desalination and mineral extraction from brines.

Our technology experts are collaborating with our operations and EHS teams to understand and apply the substantial amount of data generated by the emissions-related technologies we’re deploying. Our data science analytics team developed custom artificial intelligence (AI) models that evaluate multiple camera images of wellsites every hour to determine if the flaring equipment is functioning properly. If issues are detected, we can alert or dispatch an operator to take action.

Devon continues to invest in advanced technologies that can make help make our operations and people safer, including generative AI chatbots and apps and large learning models. We’ve trialed wearable safety devices and are excited about the potential to use augmented reality and virtual reality in safety training, as well as robotics and equipment automation to reduce risk.

Devon is empowering our employees to use AI tools to improve their productivity and use our data to its fullest potential. We collaborate closely with peer companies on using AI, drones and other rapidly advancing technologies to improve environmental and safety performance and digital security across the industry. We want to be at the forefront of adopting and applying transformational technologies that improve our ability to deliver results.

New business opportunities

In line with our ambition to provide responsibly produced energy while delivering long-term shareholder value and maintaining stakeholder trust as the world builds a reliable, secure and lower emission energy system, Devon continues to explore emerging low-emission opportunities that are complementary to our core business. These include geothermal production, electrification, produced water management, liquefied natural gas opportunities, low-carbon venture capital investments and strategic export opportunities to enhance the ultimate value of our production, among others.

Since 2023, Devon has made strategic investments totaling $117 million in Fervo Energy, a leader in next-generation geothermal technology. Fervo employs horizontal drilling, multi-stage well completion and distributed fiber optic sensing to geothermal reservoir development, including some oil and gas technologies that Devon developed over the last decade. Our engineers and geoscientists provide technical assistance and data analysis expertise to help Fervo make effective operational decisions. Given the synergies in operational practice and core competencies, this partnership underscores Devon’s commitment to creating value to power growing energy needs. We’re excited about the demand for baseload power, Fervo technology and the operational improvements Fervo is making.

Supply chain improvements

Operational excellence requires controlling costs, which we’ve accomplished with operating margin improvements, drilling and completions efficiencies, and improved supply chain efficiencies from our enhanced operating scale. One of our supply chain improvements is a first-of-its-kind mobile sand mine for completions operations we developed on surface acreage we own in the Delaware Basin. This innovative approach provides supply certainty and cost savings, and improves safety and emissions performance by reducing the number of sand trucks on roads and the combustion emissions associated with traditional mining practices.

Keeping people safe and protecting the environment are important to our daily operations, the long-term value of our company and our social license to operate. Devon takes ownership of our environmental, health, safety, operational and financial performance, and works every day to improve it.

Additional information about Devon’s performance is available in our detailed quarterly earnings presentations.